Four Track Expansion Haag - St. Valentin

Client: High-Performance Railways AG

Development Period: 1990 to 2001

During the upgrading of the railway line between Vienna and Salzburg to a high-performance track, a new 13.4 km long two-track section was built between St. Johann/Engstetten and St. Valentin. At the heart of this section is the 7 km long Sieberg Tunnel. The tunnel is consistently immersed in ground water, with only a very small overburden over significant lengths. The tunnel was constructed using different techniques: Firstly, the mining technique with multiple starting points of excavation was implemented. Secondly, towards the Western end, different types of cut and cover methods as well as an excavation below the tunnel roof, were used.

In the open areas of the route, many bridges and underpasses were built.

BGG was commissioned with the geotechnical and geohydrological consulting from the time the route was chosen, until the completion of the construction. Several subsoil exploration campaigns were performed in order to gather basic data about the underground. The exploration was done mostly by core drillings and subsequent laboratory examinations. The majority of the boreholes were developed into ground water measuring points. Based on the data gathered with this method, and in conjunction with mappings and surveys, a complete picture of the subsoil and ground water situation could be gained. The results of these examinations were used to compile geotechnical and geohydrological expert's reports required for the application of a construction permit. Geotechnical and geohydrological consulting, and a hydrogeological preservation of evidence, were provided during construction.

The "West Area":

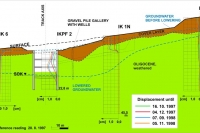

A special geotechnical challenge was presented by the west area of the Sieberg Tunnel. This area is situated in the Oligocene stratum, a geological formation extremely susceptible to slide. Besides this, the groundwater level is very high. In this area, eight inclinometers and numerous geodetic reading points were installed to monitor the slope movements. Apart from that, extensive slope draining measures had to be taken. Under these limiting conditions and according to a geomechanical model, three different construction methods were chosen along this section that provided a solution that was both technically feasible and economic.

April 2001