New Vienna - St. Pölten Railway Line,

TF 6.0 Contract Section

Client: Austrian Railways Infrastructure Construction AG

Development Period: 2003 to 2006

The project consists of a 3 km long section of the new double-track railway line between Vienna and St. Pölten. This section also includes the construction of the Hankenfeld Tunnel (length 663 m) and the Saladorf Tunnel (length 729 m) that were built using the cut and cover method. The project also included the construction of two road underpasses.

In order to minimize the disruption of an ecologically valuable habitat around the tunnel, high and steep slopes on both sides of the building pit were designed. Any failures of these slopes would have posed extreme danger to human and property safety. Therefore, they had to be properly secured according to a high safety-level, yet in a cost-effective manner. Despite an accurate subsoil exploration, several uncertainties regarding the subsoil condition could not be entirely resolved. Thus, the geotechnical safety management was of extreme importance during and after the establishment of the slope protection.

For this section, BGG Consult was responsible for the geotechnical and hydrogeological consulting and the geotechnical safety management. This regulates the construction and design processes when displacements are exceeded and/or in case of stability problems. Its aim is to minimize damage to the structures or to a third party. For this, the following services were provided:

- The expected behaviour of the system structure and subsoil were defined based on static calculations.

- The type and amount of measuring instruments were determined.

- The values for warning and alarm levels were determined.

- The organisation, evaluation and interpretation of all measurements were conducted.

- The measuring of inclinometers.

- Appropriate measures and procedures were determined where discrepancies to the expected behaviour existed.

Geotechnical Safety Management of the Saladorf Tunnel:

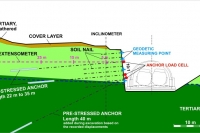

The Saladorf Tunnel was constructed using the cut and cover method. This involved that a pit slope with a length of 475 m and a height of up to 18 m had to be secured. This was accomplished by using anchored shotcrete, pre-stressed anchors and grouted soil nails.

Profiles with geodetic measuring points (up to 5 points per profile) and anchor load cells were defined every 25 m along the slope. Furthermore, five inclinometers and three 4-fold extensometers were installed.

The data was electronically read, and regularly transmitted to the monitoring station. Thus, immediately when warning or alarm values were exceeded, the appropriate people were automatically informed by the system in real-time via mobile phone. This enabled safety precautions to be executed with minimal delay.

November 2006