S 1 Motorway,

Schwechat - Ölhafen Section

Client: ASFINAG (Motorway Financing AG)

Development Period: 2004 to 2012

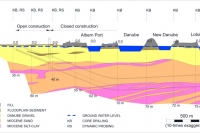

This motorway section with a length of 2.6 km is part of the Regionen Ring. The ring will form an outer circle around the city of Vienna at the eastern and northern side, and is scheduled to be completed by 2018. In the southeast area, it connects to the S 1/A 4 junction and further crosses the Danube River, the New Danube and the Lobau Port by means of a 2.3 km long tunnel that consists of two separate tubes. Originally, the project also included two connecting tunnels to the A 22 (Donauufer Motorway).

A 410 m long section of the tunnel will have to be built using the cut and cover method. This will require a building pit with a depth of up to 22 m. The bottom of the building pit will be situated 20 m below the groundwater level. For each side of the track, two lanes and an emergency lane are planned. Therefore, tunnels with diameters of 15 m are necessary.

For this project, BGG Consult was commissioned with the geological, hydrogeological, geotechnical and hydrological consultation. The services were provided in the project phases such as the preliminary design study, the building permit application, and the environmental impact assessment.

During the preliminary design study, numerous alternative routes of tunnels and bridges were evaluated.

Since the tunnels cross a nature reserve, a significant public interest was generated. This required that special attention had to be given to the public presentations.

Based on the results of a subsoil exploration campaign, expert's reports regarding the geology, hydrogeology, geotechnics and hydrology of the project were compiled. These reports were essential for the environmental impact assessment procedure.

Crossing of Danube River:

Along the route below the water bodies, an overburden of 32 m exists. The material consists of gravel, with a depth of up to 14 m below the surface, followed by miocene sand and silty clay. To a large extent, the overburden is solely made up of water permeable soil. Therefore, special attention has to be given to the groundwater situation.

Consequently, the tunnel has to be excavated using a tunnel-boring machine (TBM). Presently an excavation incorporating a slurry shield or an earth pressure balance shield is considered. Employing this technique should make these difficult subsoil conditions controllable.

December 2012